Comprehensive Guide to Choosing the Best Cold Room Supplier and Refrigeration Equipment for Your Business

In today's fast-paced commercial environment, maintaining optimal temperature control is crucial for the success of businesses involved in food preservation, pharmaceuticals, logistics, and manufacturing. The foundation of such temperature-sensitive operations is hardware and infrastructure provided by a reliable cold room supplier. This comprehensive guide aims to detail everything you need to understand about selecting the right refrigeration equipment and why partnering with a reputable cold room supplier can elevate your business performance.

Understanding the Importance of High-Quality Refrigeration Equipment

Refrigeration equipment is not just about cooling; it’s a strategic investment that directly influences product integrity, energy efficiency, operational reliability, and regulatory compliance. When you opt for superior refrigeration systems, business owners benefit from reduced waste, minimized energy costs, and enhanced customer trust.

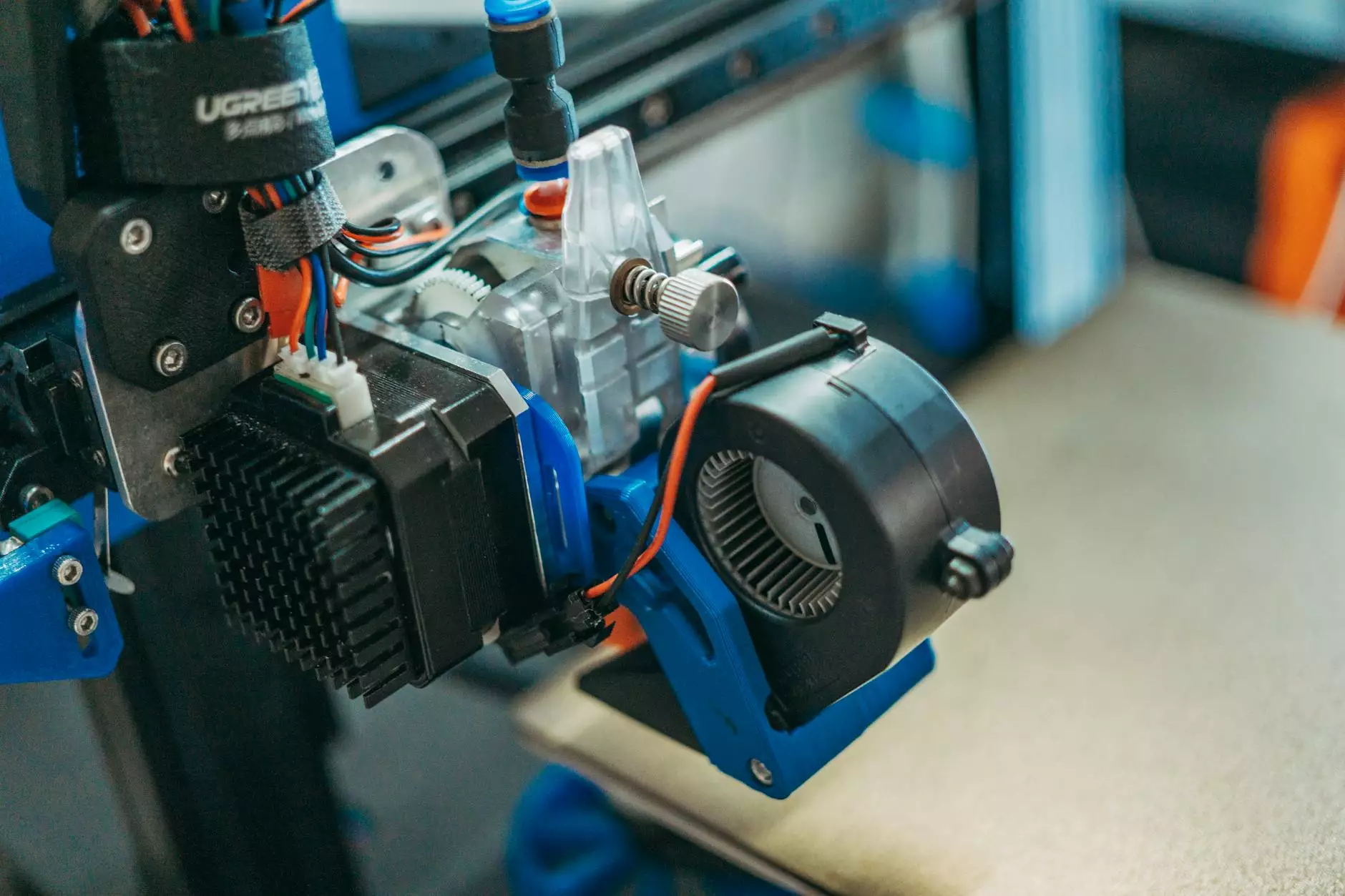

Key components of refrigeration equipment include cold rooms, walk-in coolers, freezers, chillers, and industrial refrigeration units. Each plays a pivotal role depending on the nature of your business activities.

Why Choosing the Right Cold Room Supplier Matters

A cold room supplier is your partner in designing, manufacturing, installing, and maintaining refrigeration solutions that meet your specific needs. Selecting the right provider involves careful evaluation of several factors:

- Experience and Reputation: Choose suppliers with a proven track record in delivering quality cooling solutions.

- Customized Solutions: The supplier should offer tailored designs that align with your operational requirements.

- Product Quality and Certification: Ensure the equipment complies with international standards like ISO, CE, and HACCP.

- After-Sales Support and Maintenance: Reliable service guarantees minimal downtime and quick resolution of issues.

- Cost-effectiveness and Energy Efficiency: Look for solutions that balance affordability with low operational costs.

Features to Look for in Refrigeration Equipment

Choosing high-quality refrigeration equipment involves understanding the features that can improve system performance and durability:

- Advanced Insulation Materials: Better insulation minimizes temperature fluctuations and reduces energy consumption.

- Efficient Compressors: Modern compressors offer higher efficiency and quieter operation.

- Smart Temperature Controls: Digital thermostats and automation systems provide precise temperature management.

- Corrosion-Resistant Components: Especially important for humid environments to extend the lifespan of the equipment.

- Modular Design: Allows easy expansion and maintenance without significant disruption.

The Role of Customization in Refrigeration Solutions

Every business has unique requirements. Whether you need a cold room for pharmaceuticals, a chilled storage for dairy products, or a large-scale industrial refrigeration system, customized solutions ensure optimal performance. Top cold room suppliers offer bespoke designs that incorporate:

- Precisely calibrated temperature zones

- Specific interior layouts for product segregation

- Optimized airflow systems for uniform temperature distribution

- Energy-efficient refrigeration components tailored to space size

- Seamless integration with existing logistics and storage infrastructure

Innovative Technologies Revolutionizing Refrigeration Equipment

The refrigeration industry is continually evolving, driven by advancements that improve efficiency, sustainability, and user experience. Some transformative technologies include:

- Eco-Friendly Refrigerants: Transitioning from chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) to substances like R-134a, R-410A, and natural refrigerants such as ammonia and carbon dioxide.

- Variable Speed Compressors: These optimize energy use according to real-time cooling demands, significantly reducing power consumption.

- Automation and IoT Integration: Remote diagnostics, real-time monitoring, and predictive maintenance enhance system reliability.

- Phase Change Materials (PCMs): Used for passive cooling and thermal energy storage, reducing the load on active refrigeration systems.

Choosing Your Cold Room Supplier: Key Considerations

When selecting a cold room supplier, it is essential to conduct comprehensive research and vet prospective providers thoroughly. Critical steps include:

- Assessing Experience: Prioritize companies with extensive industry experience and a portfolio of successful projects.

- Reviewing Client Testimonials and Case Studies: Look for feedback that underscores quality, reliability, and after-sales support.

- Verifying Certifications: Ensure the supplier adheres to international standards, guaranteeing safety and quality.

- Requesting Detailed Proposals and Quotes: Compare not just prices but also warranties, service packages, and maintenance options.

- Ensuring Post-Installation Support: Confirm that support and maintenance are accessible and responsive.

Best Practices for Maintaining Refrigeration Equipment

Proper maintenance extends the lifespan of your refrigeration systems, keeps energy costs low, and ensures safety compliance. Effective practices include:

- Regular Cleaning: Prevent dirt and mold buildup on coils, fans, and filters.

- Scheduled Inspections: Routine checks of compressors, thermostats, and refrigerant levels.

- Monitoring System Performance: Use smart controls to detect anomalies early.

- Timely Repairs: Address issues promptly to prevent system failures and product spoilage.

- Updating Firmware and Software: Keep automation systems current for optimal operation.

Environmental and Regulatory Compliance in Refrigeration

Adopting environmentally responsible refrigeration solutions is no longer optional but mandatory in many regions. Leading cold room suppliers emphasize sustainability by offering systems with eco-friendly refrigerants, energy-efficient compressors, and low-emission components. Ensuring compliance with local, national, and international regulations helps avoid penalties and enhances your brand’s reputation.

Why Choose First Cold Chain as Your Refrigeration Equipment and Cold Room Supplier

First Cold Chain has established itself as a premier cold room supplier dedicated to delivering innovative, reliable, and customized refrigeration solutions for diverse industries. With decades of experience, cutting-edge technology, and a customer-centered approach, First Cold Chain guarantees:

- Highest quality materials and manufacturing standards

- Tailored solutions optimized for operational efficiency

- Comprehensive after-sales service and maintenance programs

- Expert consultation to match the right equipment with your business needs

- Commitment to sustainability and eco-friendly practices

Conclusion: Investing in the Right Refrigeration Solutions for Long-Term Success

In conclusion, selecting the best cold room supplier and investing in top-tier refrigeration equipment lays the foundation for efficient, safe, and compliant storage operations. Prioritize experience, customization, technological innovation, and environmental sustainability to ensure your business remains competitive and resilient.

Partnering with a trusted provider like First Cold Chain guarantees not only quality hardware but also ongoing support that adapts to evolving industry standards and your growing needs.

Remember, temperature control is a strategic asset—invest wisely to safeguard your products, boost operational efficiency, and enhance your reputation in the marketplace.